WP_Query Object

(

[query] => Array

(

[page] =>

[pagename] => about-us/news

)

[query_vars] => Array

(

[page] => 0

[pagename] => about-us/news

[error] =>

[m] =>

[p] => 0

[post_parent] =>

[subpost] =>

[subpost_id] =>

[attachment] =>

[attachment_id] => 0

[name] =>

[page_id] => 0

[second] =>

[minute] =>

[hour] =>

[day] => 0

[monthnum] => 0

[year] => 0

[w] => 0

[category_name] =>

[tag] =>

[cat] =>

[tag_id] =>

[author] =>

[author_name] =>

[feed] =>

[tb] =>

[paged] => 0

[meta_key] =>

[meta_value] =>

[preview] =>

[s] =>

[sentence] =>

[title] =>

[fields] =>

[menu_order] =>

[embed] =>

[category__in] => Array

(

)

[category__not_in] => Array

(

[0] => 1047

)

[category__and] => Array

(

)

[post__in] => Array

(

)

[post__not_in] => Array

(

)

[post_name__in] => Array

(

)

[tag__in] => Array

(

)

[tag__not_in] => Array

(

)

[tag__and] => Array

(

)

[tag_slug__in] => Array

(

)

[tag_slug__and] => Array

(

)

[post_parent__in] => Array

(

)

[post_parent__not_in] => Array

(

)

[author__in] => Array

(

)

[author__not_in] => Array

(

)

[orderby] => date

[post_type] => Array

(

[0] => post

[1] => developer_blog

)

[post_status] => publish

[order] => DESC

[tax_query] => Array

(

[0] => Array

(

[taxonomy] => blog-group

[field] => slug

[terms] => Array

(

[0] => public

)

[operator] => IN

)

[1] => Array

(

[taxonomy] => blog-group

[field] => slug

[terms] => Array

(

[0] => general-user

[1] => technical-asociate

[2] => qualified-sales-representative

[3] => kvaser-internal

)

[operator] => NOT IN

)

)

[ignore_sticky_posts] =>

[suppress_filters] =>

[cache_results] => 1

[update_post_term_cache] => 1

[lazy_load_term_meta] => 1

[update_post_meta_cache] => 1

[posts_per_page] => 10

[nopaging] =>

[comments_per_page] => 50

[no_found_rows] =>

[taxonomy] => blog-group

[term] => public

)

[tax_query] => WP_Tax_Query Object

(

[queries] => Array

(

[0] => Array

(

[taxonomy] => blog-group

[terms] => Array

(

[0] => public

)

[field] => slug

[operator] => IN

[include_children] => 1

)

[1] => Array

(

[taxonomy] => blog-group

[terms] => Array

(

[0] => general-user

[1] => technical-asociate

[2] => qualified-sales-representative

[3] => kvaser-internal

)

[field] => slug

[operator] => NOT IN

[include_children] => 1

)

[2] => Array

(

[taxonomy] => category

[terms] => Array

(

[0] => 1047

)

[field] => term_id

[operator] => NOT IN

[include_children] =>

)

)

[relation] => AND

[table_aliases:protected] => Array

(

[0] => wp_term_relationships

)

[queried_terms] => Array

(

[blog-group] => Array

(

[terms] => Array

(

[0] => public

)

[field] => slug

)

)

[primary_table] => wp_posts

[primary_id_column] => ID

)

[meta_query] => WP_Meta_Query Object

(

[queries] => Array

(

)

[relation] =>

[meta_table] =>

[meta_id_column] =>

[primary_table] =>

[primary_id_column] =>

[table_aliases:protected] => Array

(

)

[clauses:protected] => Array

(

)

[has_or_relation:protected] =>

)

[date_query] =>

[queried_object] => WP_Post Object

(

[ID] => 1277

[post_author] => 38

[post_date] => 2014-11-21 12:03:40

[post_date_gmt] => 2013-12-19 15:28:51

[post_content] =>

[post_title] => News

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => news

[to_ping] =>

[pinged] =>

[post_modified] => 2021-08-12 09:14:30

[post_modified_gmt] => 2021-08-12 09:14:30

[post_content_filtered] =>

[post_parent] => 23

[guid] => https://www.kvaser.com/?page_id=1277

[menu_order] => 5

[post_type] => page

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[queried_object_id] => 1277

[request] => SELECT SQL_CALC_FOUND_ROWS wp_posts.ID FROM wp_posts LEFT JOIN wp_term_relationships ON (wp_posts.ID = wp_term_relationships.object_id) WHERE 1=1 AND (

wp_term_relationships.term_taxonomy_id IN (1026)

AND

wp_posts.ID NOT IN (

SELECT object_id

FROM wp_term_relationships

WHERE term_taxonomy_id IN (1025,1027,1028,1029)

)

AND

wp_posts.ID NOT IN (

SELECT object_id

FROM wp_term_relationships

WHERE term_taxonomy_id IN (1058)

)

) AND wp_posts.post_type IN ('post', 'developer_blog') AND ((wp_posts.post_status = 'publish')) GROUP BY wp_posts.ID ORDER BY wp_posts.post_date DESC LIMIT 0, 10

[posts] => Array

(

[0] => WP_Post Object

(

[ID] => 44638

[post_author] => 48062

[post_date] => 2024-04-09 09:31:25

[post_date_gmt] => 2024-04-09 09:31:25

[post_content] => [vc_row][vc_column][vc_single_image image="44641"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]AVAI (Autonomous Vehicle Artificial Intelligence), an AV design and services company, has joined Kvaser's Technical Associate (TA) and Qualified Sales Representative (QSR) program. Led by Silicon Valley autonomous vehicle veterans who have spent years designing and building some of the largest AV testing fleets in the U.S., AVAI brings a full system approach to address the key challenges facing AV design teams. With expertise in compute platforms, sensors (LIDAR, radar, IMU, GPS, cameras etc.), drive by wire integration, data collection and data management, “our aim is to eliminate the burden of adoption for customers” explains Yaman Awad, AVAI's CEO.

AVAI defines vehicles broadly, with delivery robots, off-road utility vehicles and agricultural vehicles among their clients in addition to working with automotive OEMs. What all customers share is the need for safety-critical control systems. CAN is well-used. “For the communication between ECUs and actuators within all control systems, reproducibility and consistency of performance are key. Despite new protocols entering the market, CAN still provides this high confidence message delivery, consistent latency, and ISO compliance in a cost-effective fashion,” notes Yaman.

AVAI chose to partner with Kvaser because of our reputation as ‘the best of the best’ and for the wide range of options, from data loggers to development boards. AVAI’s customers use Kvaser’s CAN interfaces to connect to the central control system for diagnostic purposes as well as sensor data transmission. Yaman notes: “Customers come to us not only for the cable harness, but the full vertical solution including software. We are very excited to partner with Kvaser, because it strengthens our line of sight from heavy R&D to a scalable production grade autonomous solution.”

Find out more about AVAI’s end-to-end autonomous driving system design, manufacturing, and AV fleet management services at www.avai.ai[/vc_column_text][/vc_column][/vc_row]

[post_title] => AVAI chooses Kvaser interfaces for AV system designs

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => avai-chooses-kvaser-interfaces-for-av-system-designs

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-23 08:16:58

[post_modified_gmt] => 2024-04-23 08:16:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=44638

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 45091

[post_author] => 910

[post_date] => 2024-03-22 00:14:18

[post_date_gmt] => 2024-03-22 00:14:18

[post_content] => [vc_row][vc_column][vc_single_image image="45093"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]There are applications for CAN tha

Electrifying trucks

While electric car chargers are common throughout much of the world, they will not be adequate for charging the heavy-duty electric powered vehicles under development. The heavy duty trucks, electric ferries, and electric aircraft now in development will require much more powerful charging stations because their battery banks are much larger, and the industries they serve require much faster recharge times.

The standard under development to meet these needs is the Megawatt Charging Standard (MCS), labelled SAE J3271 by the Society of Automotive Engineers. This is a DC charging standard that increases the amount of charge that can be delivered to vehicles that fall under its remit. There are several aspects of this application that differentiate it from the charging stations being used today. Very high reliability is one of these. Connections must consider an environment with moving parts (cables and connectors), outside temperature and moisture extremes, rough handling, and dirty conditions to name just a few. To make things more difficult, the higher power ranges of this standard require liquid cooling in the cable and connector. This will necessitate different expertise in the design of the components, and therefore different standards committees and task forces working in parallel.

Hitching trucks to trailers

In a distinctly different application t, truck/trailer connections of the near future have many of the same challenges, except for liquid cooling. Unlike most uses for CAN CC and CAN FD, these applications most likely be one ECU on each of the parts. If you study the FD, you understand why these networks are not valid networks until this connection is made. And then there is the question of termination. CAN requires a terminator on or close to each end of the trunk cable. With the cable disconnected somewhere in the middle, the termination requirements make it so neither half is a valid network on its own.

Both megawatt chargers and truck/trailer connections must consider upgradeability and longevity in relation to protocol detection and adaptation. When one ECU is plugged into another, you must know either exactly how it is configured to communicate, or be able to detect and adapt to a common communications protocol. CAN CC, CAN FD, CAN XL (a little further out), Ethernet 10Base-T1S, 1000Base-T1, and ISO 11992 with 12 or 24 volts signalling are being considered for one or both applications.

The ISO 11992 standards, used for tractor/trailer connections mostly in the European markets, have given developers experience with a few of the issues being considered in MCS and future truck/trailer interfaces. The areas of overlap are related to the requirement for high reliability, and the need for a split network with termination on each side. ISO 11992 is a proven standard that also allows for communications in fault conditions, such as single wire connections where CAN_H or CAN_L are shorted or open. The experience gained from ISO 11992 with termination on each side of the network gives us some confidence going forward, but the additional selections between networks, speeds, and protocols are requiring developers to produce novel solutions, then to prove that these solutions meet the high reliability needs of these applications.

Kvaser is an industry leader in digital control technology and will continue to monitor and contribute to these standardization processes while providing high-quality interfaces and data loggers to meet the needs of this industry.[/vc_column_text][/vc_column][/vc_row]

[post_title] => Bryan Hennessy’s Q1/2024 SAE J3271 update

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => bryan-hennessys-q1-2024-update-on-sae-j3271-the-megawatt-charging-system-standard

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-22 09:54:44

[post_modified_gmt] => 2024-03-22 09:54:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?post_type=developer_blog&p=45091

[menu_order] => 0

[post_type] => developer_blog

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 45052

[post_author] => 48062

[post_date] => 2024-03-21 23:48:51

[post_date_gmt] => 2024-03-21 23:48:51

[post_content] => [vc_row][vc_column width="2/3"][vc_column_text]TK Engineering* has packaged its CAN analyzer software, CANtrace, with a pair of Kvaser Air Bridge wireless CAN bridges and a Kvaser Leaf v3 CAN to USB interface to provide an ‘out-of-the-box’ wireless diagnostics kit for a wide range of control systems.

Applicable to maintenance, configuration and troubleshooting situations in applications such as heavy-duty vehicles, material handling, logistics, mining vehicles, construction equipment and agricultural machinery, the use of the Kvaser Air Bridge in this package particularly suits it to use cases where a traditional wired connection proves unsuitable or challenging to implement. [/vc_column_text][/vc_column][vc_column width="1/3"][vc_single_image image="45053"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]The pair of Kvaser Air Bridges extends an existing CAN network wirelessly, forming a point-to-point link to ensure reliable communication between the two parties. Then, using the Kvaser Leaf v3, this extended network communication can be monitored, analyzed, and controlled. TKE’s CANtrace CAN diagnostics software supports CANopen and J1939 protocols and offers advanced features such as real-time tracing, CAN and CAN FD (Flexible Data) decoding, and plotting of CAN messages and signals.

To find out more, please visit TKE Wireless CAN Diagnostic Package

*Please note that TKE Sweden AB supports Swedish customers with Kvaser products and TK Engineering Oy in Finland provides international support. [/vc_column_text][/vc_column][/vc_row]

[post_title] => TKE’s new Wireless CAN Diagnostics Package

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => tkes-new-wireless-can-diagnostics-package

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-21 23:48:51

[post_modified_gmt] => 2024-03-21 23:48:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=45052

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 44620

[post_author] => 48062

[post_date] => 2024-02-27 14:25:29

[post_date_gmt] => 2024-02-27 14:25:29

[post_content] => [vc_row][vc_column][vc_single_image image="41704"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Kvaser's latest software release updates our J2534 implementation for Windows, responding to new requirements in the standard. Firmware updates for Kvaser Hybrid and Kvaser DIN Rail are recommended following this update, as is a move to the latest version for users of Kvaser’s free Database Editor 3.

Notable changes and additions include:

Kvaser Drivers for Windows and CANlib SDK (v5.44):

Several updates related to J2534 make it worthwhile updating to this version, particularly for customers using the ISO15765 driver. With support added for the ISO15765_PS and FD_ISO15765_PS protocol IDs, our implementation is now CAN FD compatible. [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Firmware Tool (v4.32.630)

Kvaser DIN Rail SE410S-X10: This firmware version enables adjustable latency down to 1ms and 0 ms, which is useful when using protocols with a ping pong scheme, such as XCP and CCP. There is a throughput trade-off with lower latency values that users should be aware of.

This firmware update includes an improvement to battery charging that extends battery duration.

Kvaser Hybrid: An issue concerning the signal that controls external circuitry for LIN communication has been fixed, whereby the external 1kOhm pullup was activated by the slave instead of the master. If a Kvaser Hybrid is used as LIN master unit or LIN slave unit, we recommend an upgrade.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Kvaser Database Editor 3 (v3.23.640):

is available that fixes an issue with negative min/max values for unsigned signals. We therefore recommend that customers using this tool upgrade to this version.

All files are available for download now on the Kvaser Downloads page. [/vc_column_text][/vc_column][/vc_row]

[post_title] => Kvaser’s February 2024 Software Release

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => kvasers-february-2024-software-release

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-04 10:27:33

[post_modified_gmt] => 2024-03-04 10:27:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=44620

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 44712

[post_author] => 48062

[post_date] => 2024-02-27 14:24:06

[post_date_gmt] => 2024-02-27 14:24:06

[post_content] => [vc_row][vc_column][vc_column_text]Influx Technology has packaged its K-TC Series thermocouple data logger with a Kvaser Leaf v3 interface and Kvaser T-Cannector to deliver a simple and streamlined solution to thermocouple logging. Pairing the K-TC Series with the Kvaser Leaf v3 assures reliable and future-proof compatibility, whilst the addition of the Kvaser T-Cannector provides a simple way to power the K-TC and add it to the CAN network.[/vc_column_text][vc_column_text]The K-TC Series supports K, J, & T-type thermocouples and operates in three modes; Standalone data logging, Thermocouple to CAN, and USB to PC for live data. Galvanically isolated on the Power, USB, and CAN network, the K-TC Series belongs to Influx Technology’s stackable instrumentation range, which captures data from thermocouples, analog, digital and PWM inputs that is transmitted on the CAN Bus.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image="44713"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]The K-TC comes with free software; K-CAL and K-LOG. K-CAL provides real-time data visualisation, data export in different file formats, and CAN and thermocouple configuration. K-LOG gives access to the logged data stored in the K-TC.[/vc_column_text][vc_column_text]“By collaborating with innovative partners like Kvaser, we ensure our customers have access to the latest advancements in data acquisition technology. This collaboration will redefine the future of thermocouple data logging.” Lance Keen, CEO of Influx Technology.[/vc_column_text][vc_column_text]Find out more about Influx Technology’s K-TC Series and Kvaser Leaf v3 interface package here.[/vc_column_text][/vc_column][/vc_row]

[post_title] => Stronger together: Influx packages K-TC thermocouple logger with the Kvaser Leaf v3

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => stronger-together-influx-packages-k-tc-thermocouple-logger-with-the-kvaser-leaf-v3

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-27 14:24:06

[post_modified_gmt] => 2024-02-27 14:24:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=44712

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 44155

[post_author] => 48062

[post_date] => 2023-12-15 13:49:05

[post_date_gmt] => 2023-12-15 13:49:05

[post_content] => [vc_row][vc_column][vc_single_image image="44177" alignment="center"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]This year, in place of corporate gifts, we again donate to UNICEF, whose mission is to protect the rights and well-being of every child. UNICEF supports children with essential healthcare, education, nutrition, and protection, setting the stage for a better, more equitable world.

Here’s to a season of compassion, generosity and collective efforts to make the world a better place.

God Jul och Gott Nytt År Önskar!

圣诞快乐&新年快乐!

Merry Christmas and Happy New Year!

The Kvaser Team[/vc_column_text][/vc_column][/vc_row]

[post_title] => Kvaser supports UNICEF for global child welfare initiatives

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => kvaser-supports-unicef-for-global-child-welfare-initiatives

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 13:49:05

[post_modified_gmt] => 2023-12-15 13:49:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=44155

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 44099

[post_author] => 23

[post_date] => 2023-12-13 13:41:34

[post_date_gmt] => 2023-12-13 13:41:34

[post_content] => [vc_row][vc_column][vc_video link="https://www.youtube.com/watch?v=o8BHD6UMwrI"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]We’re delighted to share with you a video about some inspirational individuals within our midst. 'Kvaser Founders’ Story: A Journey into Our Origins' provides an insight into the people who set our company on its path and continue to inspire us with their vision, passion, and spirit of innovation.[/vc_column_text][/vc_column][/vc_row]

[post_title] => Kvaser Founders’ Story: A Journey into Our Origins

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => kvaser-founders-story-a-journey-into-our-origins

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-09 16:00:58

[post_modified_gmt] => 2024-01-09 16:00:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=44099

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 44072

[post_author] => 5

[post_date] => 2023-12-07 11:38:42

[post_date_gmt] => 2023-12-07 11:38:42

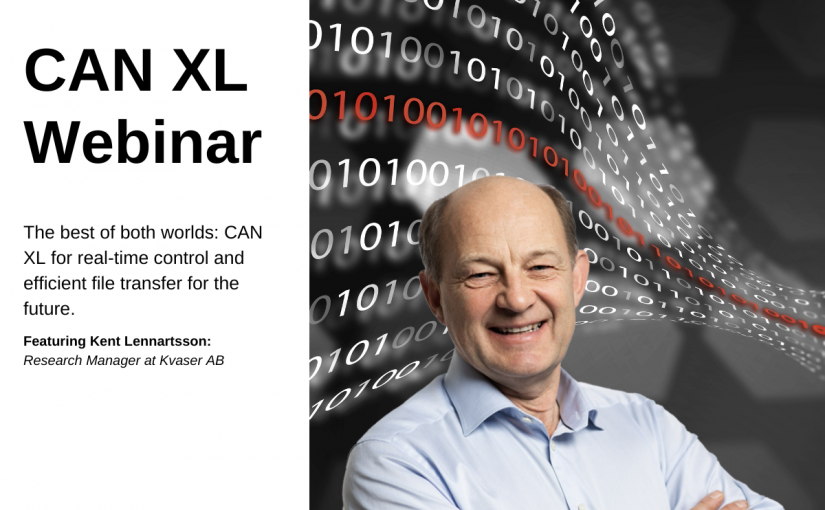

[post_content] => [vc_row][vc_column][vc_video link="https://www.youtube.com/watch?v=jvD7pJGwDeI"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Our Autumn webinar on CAN XL is now available on-demand. In this one-hour discussion, Kvaser’s Research manager, Kent Lennartsson, and Field Application Engineer, Lars-Göran Fredriksson, provide an update on CAN XL’s progress to standardization and discuss some of the practicalities of working with it at the bit level.

Learn about:

- CAN XL's backwards compatibility

- The control bit chart and higher layer support

- CAN XL bandwidth, limits and limitations

- The importance of SIC implementation (solving the ringing, achieving 10Mbits/s)

- Kvaser & CAN XL

[/vc_column_text][/vc_column][/vc_row]

[post_title] => On-demand CAN XL Webinar now available

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => on-demand-can-xl-webinar-now-available

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-11 07:56:46

[post_modified_gmt] => 2023-12-11 07:56:46

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=44072

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 43955

[post_author] => 48062

[post_date] => 2023-12-01 07:44:36

[post_date_gmt] => 2023-12-01 07:44:36

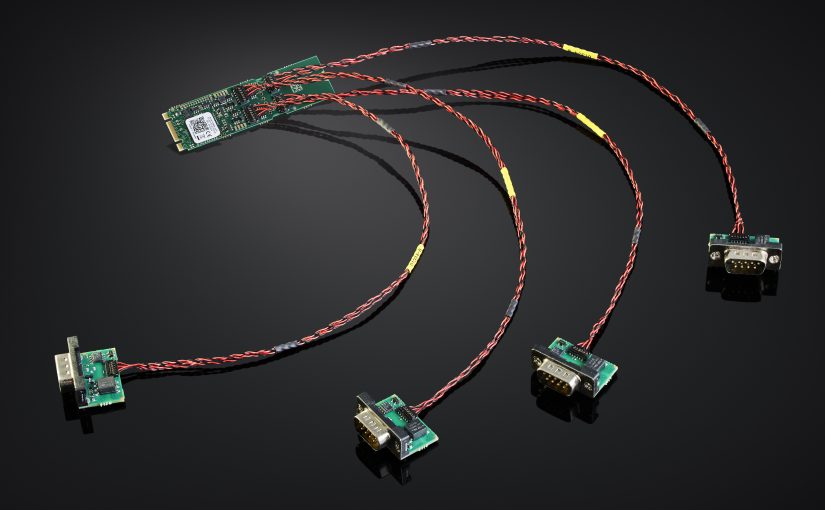

[post_content] => [vc_row][vc_column][vc_single_image image="43957"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Kvaser’s smallest embedded board is now available. The Kvaser M.2 PCIe 4xCAN (

01333-9) has four distributed controller area network (CAN) transceivers, adding high speed CAN/CAN FD to any host computer with PCI Express connectivity and an available B or M keyed M.2 slot.

This CAN interface board has a particularly compact footprint, thanks to an M.2 card size of 22 x 80 mm and industry-leading height of just 2 mm. Unique to the Kvaser M.2 PCIe 4xCAN is that the CAN transceivers are distributed (off-board), allowing them to be located closer to the CAN networks themselves. This layout maximises signal speed and integrity, making it ideally suited for CAN FD.

Each CAN module connects to the M.2 card using 30 cm long PCB-to-PCB cabling. The distributed CAN layout is particularly suited to systems with enclosures. As each CAN channel is individually isolated, optimal galvanic isolation can also be assured. This board’s operating temperature is within the standard industrial range of -40 to 85oC.

With a time stamp resolution of just 1 μs and a maximum message rate of 20000 msg/s per channel, plus advanced features such as silent mode, error frame detection and generation, this advanced board with distributed CAN transceivers can be integrated in a wide range of embedded systems. Examples range from motor control for mobile robots, automated driving simulation black boxes, to CAN data acquisition in medical automation, fleet management or industrial system monitoring.

“

The Kvaser M.2 PCIe 4xCAN board’s exceptionally small and ultra-slim footprint is a natural progression of our PCI Express range, responding to calls from customers for off-board transceivers,” comments

Martin Sventen, CEO of Kvaser AB. “

Multiple boards can be combined to provide 8, 12 or more CAN channels within a very small footprint. We see some very exciting use cases for our boards in this format.”

Kvaser’s free-of-charge CANlib SDK can be used to develop software for the Kvaser M.2 PCIe 4xCAN. Programs written in CANlib, which supports Windows and Linux, are fully compatible with present and future Kvaser hardware[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]More information about the new Kvaser M.2 PCIe 4xCAN, including full performance and technical specifications, can be found at the

product page.

For other cable length or connector types, please contact us for customized options. Click

here for more information.[/vc_column_text][/vc_column][/vc_row]

[post_title] => Kvaser unveils a compact embedded board with four distributed CAN modules

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => kvaser-unveils-a-compact-embedded-board-with-four-distributed-can-modules

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-01 07:44:36

[post_modified_gmt] => 2023-12-01 07:44:36

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=43955

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 43662

[post_author] => 23

[post_date] => 2023-11-01 00:50:23

[post_date_gmt] => 2023-11-01 00:50:23

[post_content] => [vc_row][vc_column width="1/2"][vc_single_image image="43680"][vc_column_text css=".vc_custom_1698799048880{padding-left: 40px !important;}"]

Kvaser Leaf Light HS v2

[/vc_column_text][vc_column_text]

- Only 8,000 messages per second

- Only Classical CAN

- No Silent Mode

- 100 µs Timestamp Resolution

[/vc_column_text][vc_btn title="Visit the Kvaser Leaf Light HS v2 product page" link="url:https%3A%2F%2Fwww.kvaser.com%2Fproduct%2Fkvaser-leaf-light-hs-v2%2F|target:_blank"][/vc_column][vc_column width="1/2"][vc_single_image image="43681"][vc_column_text css=".vc_custom_1698799079279{padding-left: 40px !important;}"]

Kvaser Leaf v3

[/vc_column_text][vc_column_text]

- 20,000 messages per second

- Classical CAN & CAN FD

- Silent Mode

- 50 µs Timestamp Resolution

[/vc_column_text][vc_btn title="Visit the Kvaser Leaf v3 product page" link="url:https%3A%2F%2Fwww.kvaser.com%2Fproduct%2Fleaf-v3%2F|target:_blank"][/vc_column][/vc_row][vc_row css=".vc_custom_1698799744346{padding-top: 30px !important;}"][vc_column][vc_column_text]

Silent Mode places the device in a listen-only mode. Perfect for monitoring bus traffic without fear of disrupting communication.

CAN FD brings the Leaf into the next generation of CAN communication. Now you can interface with classical CAN or CAN FD buses with just one device.

Sharper Timestamp Resolution means more precision than ever before.

Thanks to Our Universal API, adding support for the new Leaf v3 is incredibly simple.

Kvaser’s Dedicated Support Team will leave you feeling secure knowing the technical support you need is just a phone call or email away.

2 Year Warranty: See our General Conditions and Policies for details.

[/vc_column_text][/vc_column][/vc_row]

[post_title] => The Kvaser Leaf v3: New Features, Same Great Look

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => the-kvaser-leaf-v3-new-features-same-great-look

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-11 08:48:59

[post_modified_gmt] => 2024-04-11 08:48:59

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=43662

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 10

[current_post] => -1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 44638

[post_author] => 48062

[post_date] => 2024-04-09 09:31:25

[post_date_gmt] => 2024-04-09 09:31:25

[post_content] => [vc_row][vc_column][vc_single_image image="44641"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]AVAI (Autonomous Vehicle Artificial Intelligence), an AV design and services company, has joined Kvaser's Technical Associate (TA) and Qualified Sales Representative (QSR) program. Led by Silicon Valley autonomous vehicle veterans who have spent years designing and building some of the largest AV testing fleets in the U.S., AVAI brings a full system approach to address the key challenges facing AV design teams. With expertise in compute platforms, sensors (LIDAR, radar, IMU, GPS, cameras etc.), drive by wire integration, data collection and data management, “our aim is to eliminate the burden of adoption for customers” explains Yaman Awad, AVAI's CEO.

AVAI defines vehicles broadly, with delivery robots, off-road utility vehicles and agricultural vehicles among their clients in addition to working with automotive OEMs. What all customers share is the need for safety-critical control systems. CAN is well-used. “For the communication between ECUs and actuators within all control systems, reproducibility and consistency of performance are key. Despite new protocols entering the market, CAN still provides this high confidence message delivery, consistent latency, and ISO compliance in a cost-effective fashion,” notes Yaman.

AVAI chose to partner with Kvaser because of our reputation as ‘the best of the best’ and for the wide range of options, from data loggers to development boards. AVAI’s customers use Kvaser’s CAN interfaces to connect to the central control system for diagnostic purposes as well as sensor data transmission. Yaman notes: “Customers come to us not only for the cable harness, but the full vertical solution including software. We are very excited to partner with Kvaser, because it strengthens our line of sight from heavy R&D to a scalable production grade autonomous solution.”

Find out more about AVAI’s end-to-end autonomous driving system design, manufacturing, and AV fleet management services at

www.avai.ai[/vc_column_text][/vc_column][/vc_row]

[post_title] => AVAI chooses Kvaser interfaces for AV system designs

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => avai-chooses-kvaser-interfaces-for-av-system-designs

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-23 08:16:58

[post_modified_gmt] => 2024-04-23 08:16:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://www.kvaser.com/?p=44638

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 469

[max_num_pages] => 47

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] => 1

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => 811a2630e83cf77d928ac7693cbaf753

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

)

AVAI chooses Kvaser interfaces for AV system designs

09/04/2024

AVAI (Autonomous Vehicle Artificial Intelligence), an AV design and services company, has joined Kvaser’s Technical Associate (TA) and Qualified Sales… Read More

Read More

Bryan Hennessy’s Q1/2024 SAE J3271 update

22/03/2024

There are applications for CAN that are considered non-traditional; not the fixed layout control system found in most CAN applications. Two… Read More

Read More

TKE’s new Wireless CAN Diagnostics Package

21/03/2024

TK Engineering* has packaged its CAN analyzer software, CANtrace, with a pair of Kvaser Air Bridge wireless CAN bridges and… Read More

Read More

Kvaser’s February 2024 Software Release

27/02/2024

Kvaser’s latest software release updates our J2534 implementation for Windows, responding to new requirements in the standard. Firmware updates for… Read More

Read More

Stronger together: Influx packages K-TC thermocouple logger with the Kvaser Leaf v3

27/02/2024

Influx Technology has packaged its K-TC Series thermocouple data logger with a Kvaser Leaf v3 interface and Kvaser T-Cannector to… Read More

Read More

Kvaser supports UNICEF for global child welfare initiatives

15/12/2023

This year, in place of corporate gifts, we again donate to UNICEF, whose mission is to protect the rights and… Read More

Read More

Kvaser Founders’ Story: A Journey into Our Origins

13/12/2023

We’re delighted to share with you a video about some inspirational individuals within our midst. ‘Kvaser Founders’ Story: A Journey… Read More

Read More

On-demand CAN XL Webinar now available

07/12/2023

Our Autumn webinar on CAN XL is now available on-demand. In this one-hour discussion, Kvaser’s Research manager, Kent Lennartsson, and… Read More

Read More

Kvaser unveils a compact embedded board with four distributed CAN modules

01/12/2023

Kvaser’s smallest embedded board is now available. The Kvaser M.2 PCIe 4xCAN (01333-9) has four distributed controller area network (CAN)… Read More

Read More

The Kvaser Leaf v3: New Features, Same Great Look

01/11/2023

Kvaser Leaf Light HS v2 Only 8,000 messages per second Only Classical CAN No Silent Mode 100 µs Timestamp Resolution… Read More

Read More

youku

youku